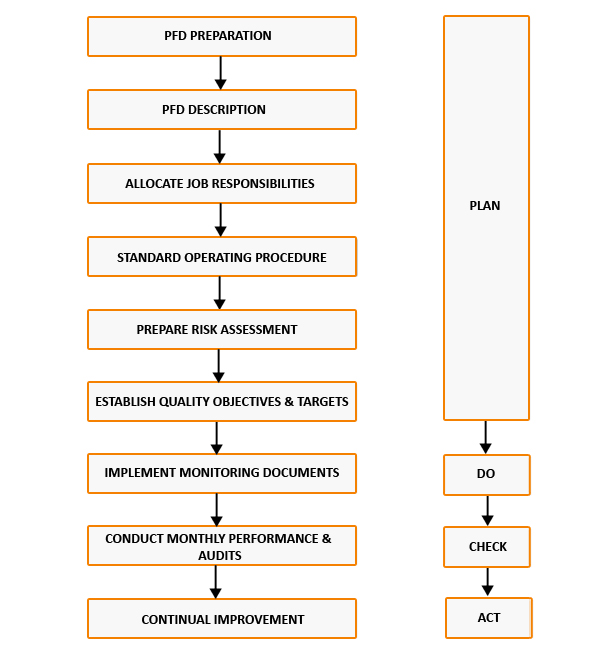

System implementation is a management system, which can be built as per ISO 9001:2015. So that, organization control towards production and quality can be enhanced.

Interaction with concerned process HOD’s to know their process and interactions to prepare the PFD.

Prepare the descriptive procedure about process and the interactions with monitoring documents and responsibility for clear understanding.

Based on the interaction with key personnel’s in system implementation, prepare the job responsibilities for all personnel’s.

Preparation of brief standard operating procedure for all departments in order to ensure the good operating condition.

Based on the standard operating procedure, risk assessment should be done to mitigate the risks.

Based on the interaction with process HOD’s, assign the quality objectives and targets which should be specific, measurable, achievable, realistic and time bound.

Based on the quality objectives and targets, list of monitoring documents should be established, implemented and followed in order to analyze the performance and effectiveness of the quality management system.

Monthly performance and Audits has been conducted in all process to check the achieved against the target. So that, further optimization and continual improvement should be done. Also, all the documents should be reviewed once in a year for further updates. Once the target is achieved, new target should be fixed during monthly performance meeting or Management review meeting.